What Are Pharmaceutical Quality Control Laboratories and Why Are They Important?

By :Dr. Dhriti Tupe, GxP Expert ®

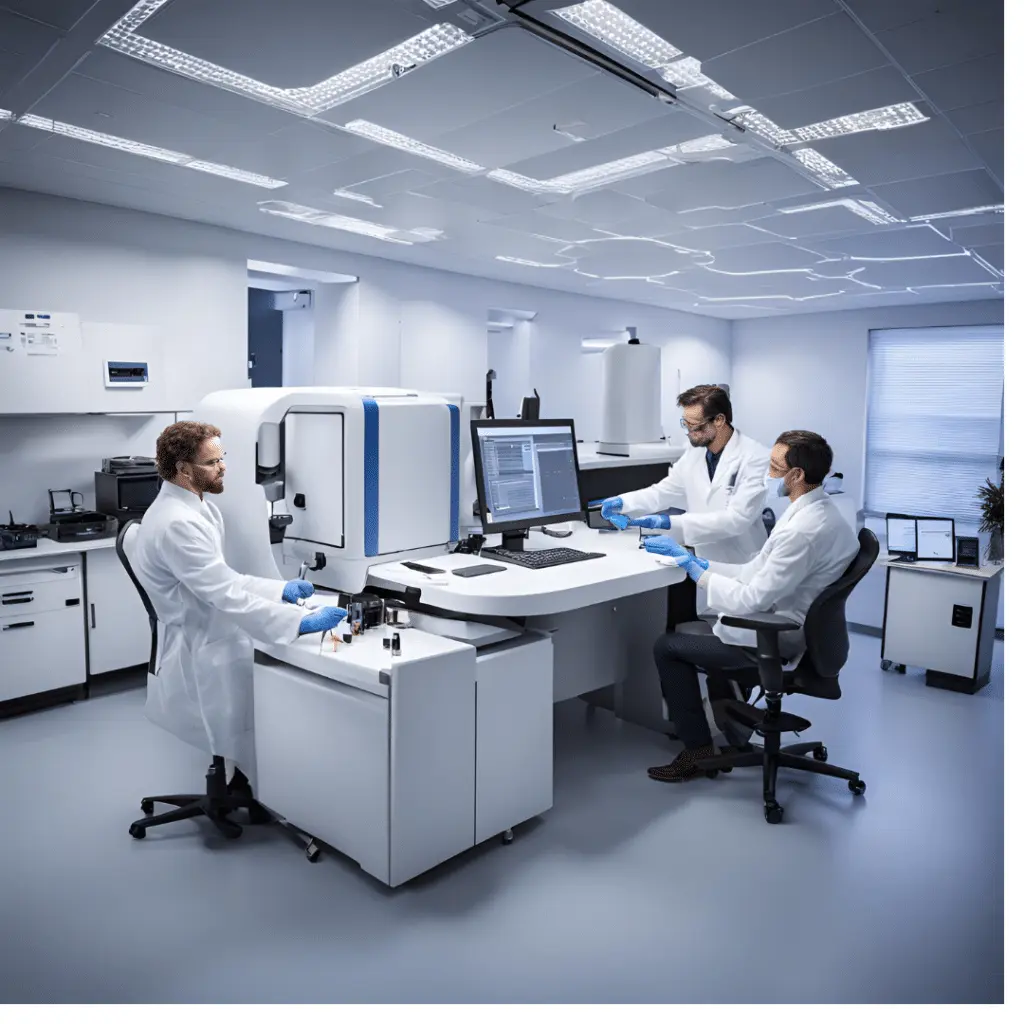

In the pharmaceutical industry, Quality Control (QC) laboratories play a vital role in ensuring the safety, efficacy, and quality of pharmaceutical products. These laboratories are essential to maintaining the integrity of the drug manufacturing process, from raw materials to the final packaged product.

What Are Pharmaceutical Quality Control Laboratories?

Pharmaceutical Quality Control laboratories are specialized facilities responsible for testing and analyzing raw materials, in-process samples, and finished products. These labs are equipped with sophisticated instruments and highly trained professionals who carry out a range of tests to ensure products meet stringent regulatory standards.

The key activities of QC laboratories include:

Chemical Testing:

Analysing the chemical composition of raw materials and finished products to ensure they meet specifications.

Microbiological Testing:

Checking for harmful microorganisms that could contaminate the product.

Physical Testing:

Verifying the physical properties of products, such as tablet hardness or dissolution rates.

Stability Testing:

Monitoring how products perform under various environmental conditions over time.

Why Are QC Laboratories Important in Pharma?

The significance of QC laboratories lies in their ability to ensure that every batch of pharmaceutical products is safe, effective, and meets regulatory requirements. Here are a few reasons why these labs are crucial:

1. Ensuring Product Safety:

Pharmaceutical products must be free from harmful contaminants. QC labs perform rigorous testing to detect any impurities, ensuring that medications are safe for consumption.

2. Compliance with Regulations:

Regulatory bodies such as the FDA and WHO have strict guidelines on the quality of pharmaceutical products. QC labs help companies comply with these guidelines by providing evidence that products meet all required standards.

3. Maintaining Product Consistency:

Every batch of a pharmaceutical product must have the same potency, purity, and quality. QC labs perform batch testing to confirm that the products are consistent and reliable.

4. Preventing Drug Recalls:

A failure in quality can lead to costly recalls, which damage both the company’s reputation and consumer trust. QC labs help mitigate this risk by catching potential issues early in the production process.

5. Supporting Continuous Improvement:

QC data provides insights that help pharmaceutical companies identify areas for improvement in their manufacturing processes, leading to better efficiency and product quality over time.

Summary

Pharmaceutical Quality Control laboratories are the backbone of product safety and efficacy in the pharma industry. They ensure that every product that reaches the market meets the highest quality standards, safeguarding public health and maintaining regulatory compliance. Without the diligent work of QC laboratories, the pharmaceutical industry would struggle to maintain the trust and safety required in drug development and production.

#Pharma #QualityControl #QC #PharmaceuticalIndustry #ProductSafety #Compliance #GMP #Laboratories #Regulations

Written By :

Dr. Dhriti Tupe, GxP Expert ®

Quality Compliance Lead Mentor Ph.D. MBA LLS- MB, GB, BB LSS-Minitab LSS Expert-Harvard Publishing Case Studies LLS-Healthcare CQA and IRCA Certified ISO 9001:2015 Lead Auditor GxP Consulting Adviser Pfizer