The Importance of Chemistry, Manufacturing, and Controls (CMC) Regulatory Documentation in Pharmaceuticals

Chemistry, Manufacturing, and Controls (CMC) regulatory documentation is a critical component in the pharmaceutical and biological product development process. It ensures that these products meet the necessary standards for quality, safety, and efficacy. Below are some key components that make up CMC documentation:

1. Drug Substance Information

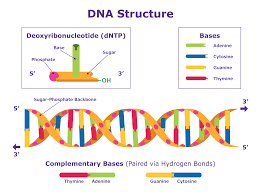

Description and Characterization: This includes detailed information about the chemical structure, molecular weight, physical properties, and characterization of the active ingredient.

Manufacturing Process: It outlines the synthesis, purification, and controls implemented during the manufacturing process.

Specifications: These are the criteria set for identity, purity, potency, and overall quality of the drug substance.

2. Drug Product Information

Formulation: This section provides a comprehensive breakdown of the final product’s composition, including active and inactive ingredients and their respective functions.

Manufacturing Process: It details the steps involved in producing the final dosage form, along with the in-process controls to maintain quality.

Specifications: Standards are set for raw materials, intermediates, and the finished product to ensure consistent quality.

3. Analytical Methods

Validation: This involves procedures to confirm that the methods used for testing are accurate, reliable, and repeatable.

Testing: It covers the specific methods used to assess the quality of both the drug substance and the final drug product.

4. Stability Data

Studies: This section contains data on how the drug substance and product maintain their quality over time when subjected to different environmental conditions.

Shelf-life: It involves determining the expiration date of the product based on stability studies.

5. Batch Records

Documentation: Batch records are comprehensive documents that track the entire manufacturing process for each batch, including the use of raw materials, processing steps, in-process controls, and the results of final product testing.

6. Regulatory Compliance

Submissions: This involves the preparation and submission of required documents to regulatory agencies, such as Investigational New Drug (IND) applications and New Drug Applications (NDA).

Quality Control: Ongoing measures are in place to ensure continuous compliance with regulatory standards, ensuring the product’s integrity throughout its lifecycle.

By adhering to these components, pharmaceutical and biological products can meet the stringent regulatory requirements necessary for market approval, ensuring that they are safe, effective, and of high quality for consumer use.